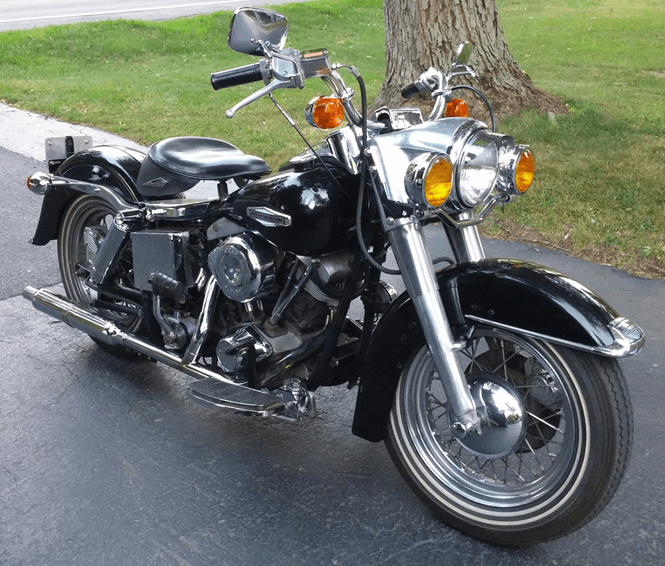

Goin’ Down Swingin’

The closer I got to finishing this shovel, the more it felt like the bike was fighting me at every single turn. Clearly, it is an inanimate object and cannot actually fight me – or can it? This bike was gonna go down swinging, but I was gonna win. I was gonna ride this damn bike to PA, and that was that. As long as it let me…

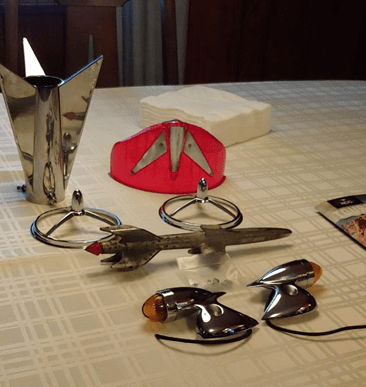

Once I got all the electrical gremlins sorted, I turned my attention to clearance issues I’d discovered with the spotlights and front turn signals. In the trailer, on the way to Dan’s, the bar on the spotlight bracket hit the top of the rocket fender ornament, so it was obvious there was a problem there. Unless you are Dan and already know it, you can’t figure out all your clearances with a bike on the lift, and the bars locked in straight ahead. I also found that where I had the front turn signals mounted, they would hit the front crash bar when I turned the bars all the way right or left.

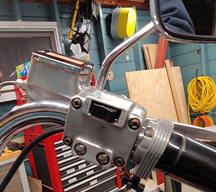

So Dan ordered the spot brackets, and the stanchions I needed to install the turn signals directly below the spots, on the same bracket. I got those installed, using a nifty deep socket Dan modified to allow you to tighten the spotlight without pinching the wire that comes through the threaded post. If I’d tried installing those lights anywhere but at Dan’s, I would still be trying to get them on.

We worked out some other bugs as well. Replaced the socket head cap screws that I initially mounted the saddle bags with because the heads were actually touching the saddle bag lids. The replacement bolts were too long, so I had to grind them down. But they have enough clearance so the lids won’t get ripped up. Calling that a win.

I got some more chrome pieces back on – frame cover beneath the seat, etc.

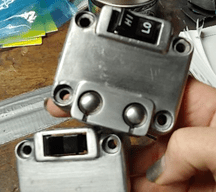

I mentioned that I wished I had a trip odometer reset stem. The trip-o is on the bike, and there was a hole in the side of the dash where, ostensibly, the stem was supposed to go, but the hole had a chrome cap plug in it. Dan had a stem, so he put it on, and when I tried to put the dash on, we found that the hole in the side of the dash wasn’t in the correct location for the stem. Of course. That explains why there was no stem already on the bike. So Dan drilled the dash, and I happened to have a rubber grommet that fit because the chrome cap would no longer work there. I popped the grommet in and filled the hole with silicone – good enough. I now have a working trip-o. Another win.

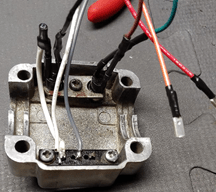

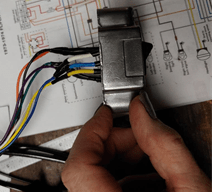

Got the dash on. Then off. Then on. Then off. Still off. Oil pressure light wasn’t working. We discovered that it was not hooked up at all. Not even sure how that happened, but OK… Then discovered that the terminals on the ignition switch are all stripped. Seriously! The shovel was going to fight me to the bitter end. So I had to go off on an expedition to find screws and nuts to finish the ignition switch, put the dash on, finally, and leave it on.

To my surprise, I actually found the microscopic screws and nuts I needed for the ignition switch. OK, they weren’t actually microscopic, but they were 3mm, which is pretty much the same thing. Needed medical forceps to hold them under the switch while I tightened the screws up top, but I got them all in, and everything was nice and snug.

To fix the oil pressure light – instead of taking the dash off, which is a pain with the tanks on – I just extended the wire and hooked it to the ignition switch. Whatevs. Done. Oil pressure light works.

Put the coil cover back on, but of course, to do that, had to remove the coil… Again… Put the cover on, and then put the whole thing back on the bike. At season end, I need to pull the two screws that hold that cover on, and replace them with hex bolts. Kinda tough to turn a socket head screw if you can’t get to the end of it.

Next up was putting the battery cover back on. Simple enough, right? Yeah, no. I was tightening a nut down on one of the bolts, and sheared the bolt clean in two! I am really not that strong. Am I? Fortunately Dan had a spare – it’s a rubber mount with bolts out each side. Not exactly something you can go to the local hardware store and pick up. However… Getting the mount back into position was…. Interesting… But I got it. Win.

The battery box strap needed a mod to accommodate the battery, so Dan took care of that for me later.

Meahwhile… I put the temporary straps back on the battery because it was finally time to dyno the bike. The day I had been waiting for!!!!!!

Added oil – all good. Added some gas – all good – but needed to reroute one gas line. Got that done with surprisingly little spillage.

Once Dan got the bike on the dyno, he made a couple mods to the Super E, and the bike ran great. It’s got 48-49 hp and tons of torque, just like it should. I didn’t have Dan dyno the bike to make it a screamer. I wanted to make sure the carb was set up correctly. He could probably have done it without the dyno because he’s done so many, but the whole process gave me peace of mind that I never had with the bike before. When I got the bike, it had the S&S Super B on it, and all I did was fight with it. Idled badly, ran badly, fouled plugs, made me crazy.

I bolted up a Super E, Dan tuned it and it’s a different bike altogether. Idles nice and smooth, and with all the torque, pulls like a freight train. Now the carb, motor and exhaust all play well together.

One final adjustment before we put the shovel on the road for a test ride. The clutch. It was adjusted completely backwards from how it should have been. I always wondered why the bike felt like it was going to pull through the clutch any second if I was in gear at a stop. Now I know. Dan showed me how to adjust it correctly, and now it will not do that anymore.

Overall, the bike ran fantastic. With the clutch adjusted, the tranny shifts a lot smoother, and with the carb adjusted correctly, the motor is happy. Finally. I have one or two tweaks on the carb to try, and I think that will put it exactly where I want it. I put about 30 miles on it – not a bad run for a first shakedown ride. I was still waiting for the correct spotlight brackets, so I still couldn’t bring the bike home. But I was so close.

When the spotlight brackets came in, I went back out to Dan’s to get them installed. I was under no illusion however, that this would be a quick, easy install.

So the brackets. The “pretty side” went toward the inside, never to be seen. The outside, that is seen had a rougher finish, and you can see the spot welds. Seriously. Not much to do about that, so I just put them on. Glory be! They fit! OK, that made up for any lack of finish quality. Win.

Turn signal stanchions. Look great. Came with zero hardware. I am lucky Dan has a lifetime collection of spare (almost) everything, so we found four screws that will work. I still need to replace them because they are black oxide, and they should be stainless. But I can do that later on my own. I just have to remember to have my Allen wrench cut down so I can get those blasted screws in and out.

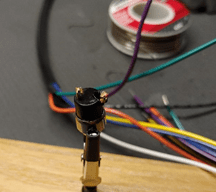

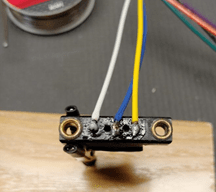

On to the turn signals. Well, with this new bracket/install, the wiring runs a little differently, so I had to rewire the turn signals. The way they were, there was a solder joint right where I needed to be able to bend the wire. No bueno. I prepped everything, and Dan soldered up the little metal contact to the new wire.

Moving to the spots. Well, those came with the bike. And they weren’t really mounted well before. Now that I had to mount them in this configuration, I was missing a critical (and of course, specialized) spacer that would allow the spots to seat properly, and also allow them to be adjusted somewhat. What to do… Well, I think Dan either felt sorry for me, or he wanted me out of his hair…. Regardless, he turned up the 2 pieces I needed on his lathe. This guy is good. Made two identical pieces – never measured a thing. I’ve worked around machinists every day for the last 20 years, so I’m not easily impressed, but Dan is impressive.

So, finally, I got the lighting assembled, but not before I needed a special deep socket that Dan had modified for this specific type of lighting set up, which I mentioned earlier. Without it, I would still be trying to tighten those spots.

I was at a stopping point, so I decided to finish everything up the following day. There wasn’t much left. Heat shrink the spot/turn signal wires, route them to the front block, wire them in, and test. So far, so good. My happy was getting happier.

It was starting to get dark out, so I put the headlight in, thinking I’d align it once I got the windshield on – it wasn’t dark enough yet – and then finish off with the beauty ring and visor.

Headlight install – check. Still works – check.

Windshield. So this windshield gets bolted on, using one of the bolts that holds the nacelle, and the spotlight brackets on. It goes into a threaded hole in the triple tree. I hate putting these bolts in and taking them out. They always go in a little hard, and I am constantly worried that I’m going to strip the threaded hole. But, so far, so good. (These previous statements are called foreshadowing….) I got three of four bolts in, so the windshield was on, except this last bolt. I was snugging it down, and it went from snug to loose…and I stripped the hole. OK. Deep breath. Dan checks it. Yep, she’s stripped. Headlight comes back out (also sketchy, as that requires steel screws into aluminum…so many ways to screw up a bike, so little time). Windshield off. Spot bracket off. Took the left side of nacelle off.

Threaded hole is fine. WHAT???? That left both of us scratching our heads. So, with Dan driving, we replaced each piece, one at a time. Nacelle, spot bracket, windshield. Each time, the bolt held. We are both still scratching our heads… But we locktited that sucker in and had a celebratory adult beverage.

Another late one, so we called it a night and I arranged to come out the following day to put the beauty ring and visor on the headlight, and ride the Atomic Shovel home.

At this point, I think I simply wore that shovel down. It had no fight left in it the next day, so I successfully finished up the headlight and rode it out of Dan’s shop.

May 31, 2019 6:15 p.m. The shovel was officially done, inspected, and on the road!